Anatomy of a 3D Printer

This post is relevant to desktop FDM type 3D printers. The principles are the same for advanced printing processes such as sintering or direct light processing though there are some additional tweaks. Most desktop printers that you’d buy in a store will be FDM type, though sintering is increasingly available.

Here’s the video:

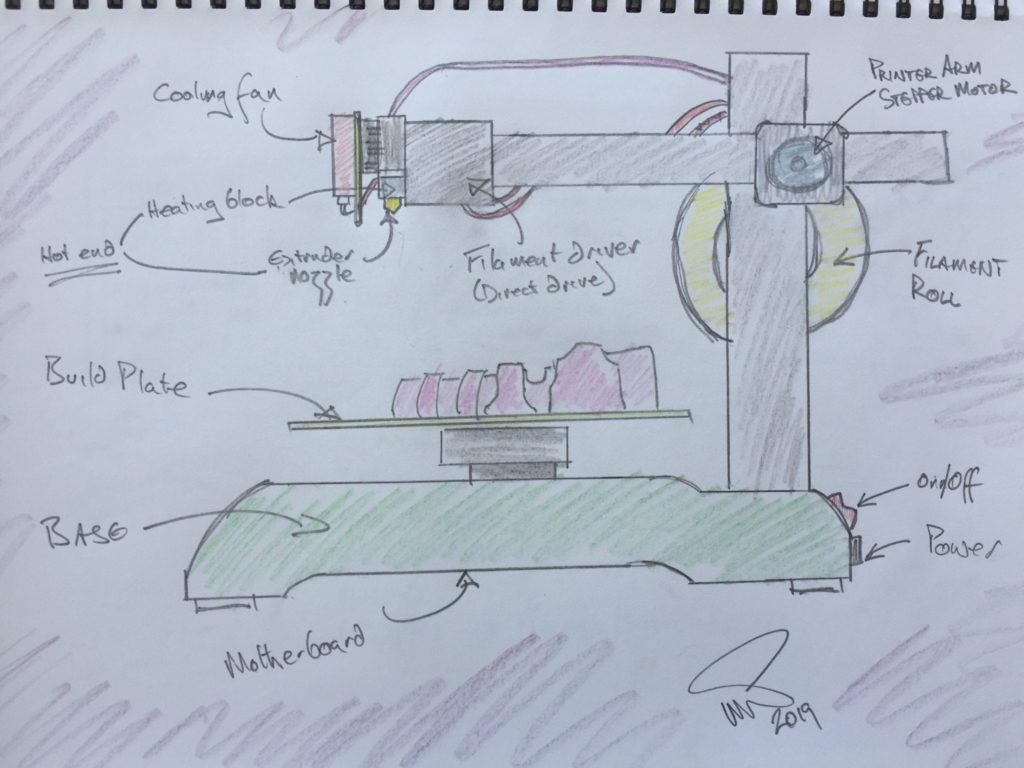

A 3D printer has some core components:

- A base

- A motherboard – This is where the 3D model software code is converted to printer movement, filament extrusion speed and temperature control.

- Printer arms – These provide the X, Y and Z axis movements

- Stepper motors – These are simple, high torque motors that drive printer and filament movements.

- A drive system – Usually either a direct drive or Bowden Tube drive system (see below).

- The printer head – Made up of the cold end and the hot end.

- The cold end – This is the part that feeds the filament into the hot end and is composed of a feeder tube, a fan, a heat sink and in the case of a direct drive system, the driver mechanism with the gear, the hobbed bolt and the idler wheel.

- The hot end – This is the part that melts the filament and extrudes it on to the build plate. It is composed of the heat break, the heater block, the extrusion nozzle, the heating wires and a thermistor.

Direct drive versus Bowden tube system.

- The best explanation that I have found is here: DIRECT VS BOWDEN EXTRUDER – Extrusion 101 (All3DP.com)

Extruder nozzles

- All3DP has a good guide on this topic as part of a broader discussion on the Cold End and the Hot End: 3D Printer Extruder Guide – All You Need to Know in 2019 (All3DP.com)

3D PRINTING

Gutenberg’s Grandchild

A Dubliner living in Sydney. Critical care (ED, ICU) and motor sport physician. FOAMed knowmad. Podcaster, 3D printing tinker and digital reality journeyman. Bassist and drummer. Cyclist. | @rollcagemedic | Website |

In some Canon Printer the users get these manual features so that they can make an easy access. If they face errors like Canon Error Code B203 that must be resolved by them only.